Projects

Detect Water Soldier RGB Drone Monitoring And Tracking

In late 2024, Saiwa Co and Ducks Unlimited Canada launched a project to improve the detection and monitoring of the invasive aquatic plant Water Soldier using drone imagery and deep learning. The plant threatens biodiversity and waterway management in ecosystems like Ontario’s Trent-Severn Waterway. Traditional control methods have limited success, making early detection critical.

The project uses UAV-captured RGB images and machine learning models to identify Water Soldier, even when partially submerged. Challenges include overlapping vegetation, variable water clarity, and lighting conditions. To address these, the team implemented a lightweight, customized deep learning solution optimized for real-time drone use.

The outcome is a scalable, proactive approach to managing invasive species, reducing both ecological and economic impact.

Automatic Pine Cone Pollination Bag Counting Using Drones

In early 2025, Saiwa and Airwyse collaborated to automate counting of pollination bags in pine orchards using autonomous drones and AI-driven image analysis. This innovative solution replaced labor-intensive manual counting, improving accuracy and efficiency in yield prediction. Tested on 44 pine trees, the system demonstrated promising results, paving the way for scalable orchard management automation.

AI-powered Vision Metrics

We at Saiwa Inc. are thrilled to announce the successful completion of an innovative project focused on the measurement of interpupillary distance (IPD) and pupil height. This groundbreaking solution was developed in collaboration with Innovation Venture Farm to address the growing need for precision in optical device fitting and design.

By leveraging cutting-edge AI techniques and the Mediapipe framework, our solution detects and calculates critical parameters such as the center of the pupil and the lowest point of glasses lenses. These measurements are crucial for applications in eyeglasses, VR/AR headsets, and other optical technologies. The results are delivered with unmatched accuracy and efficiency, empowering manufacturers to deliver tailored products to their users.

This project also integrates Saiwa’s Annotation Services, which ensure data labeling precision and scalability, making it easier for users to achieve reliable outcomes.

Fleabane Detection in Soybean Farms of Canada

Powered by Sairone and funded by OAFRI, this project leverages AI and drone imagery to detect herbicide-tolerant Canada Fleabane in Ontario soybean fields. Designed to empower farmers with no-code tools, it transforms raw agricultural images into actionable insights—enabling geotagged weed detection, herbicide mapping, and data ownership. By lowering tech adoption barriers, this initiative supports sustainable, privacy-first farming across Canada.

Paper Surface Defect Detection

Discover how Saiwa Inc. leveraged cutting-edge AI and deep learning to detect surface defects on both white and black paper with high precision. This project revolutionized quality control for a leading paper manufacturer—improving accuracy, reducing waste, and enabling real-time defect insights.

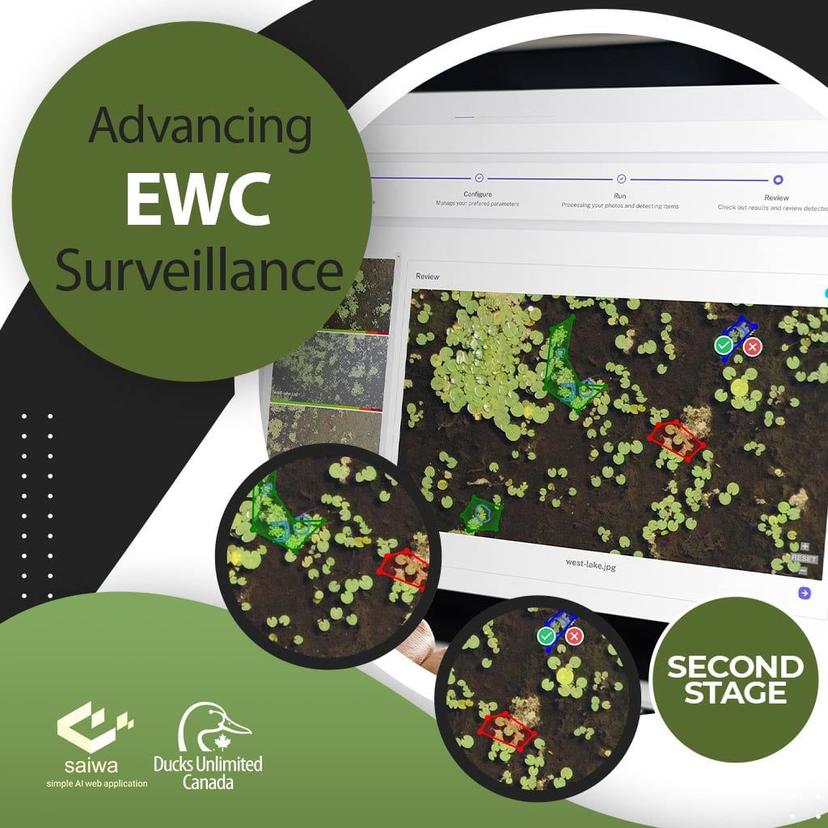

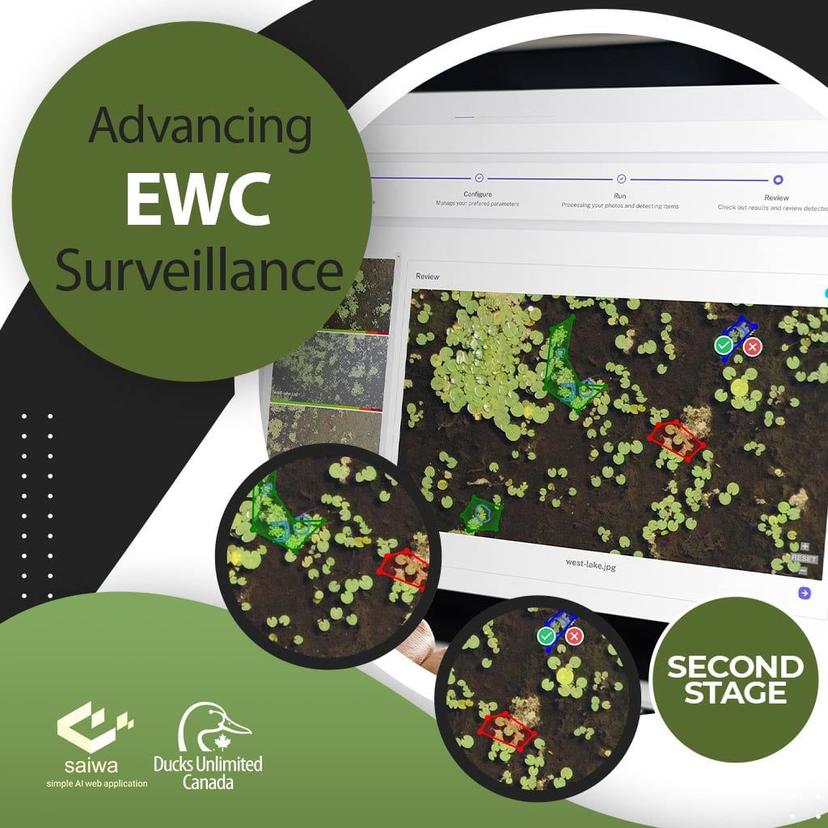

Advancing UAV-based EWC surveillance

To enhance Ducks Unlimited Canada (DUC)‘s capability for UAV-based surveillance of European Water Chestnut (EWC) through machine learning, we at Saiwa have previously implemented the initial version of the EWC detector software. In the second stage, we are in the process of finalizing the product’s features and upgrading its interfaces.The two primary features to be incorporated in this stage are as follows:

Incremental learning for gradually training the deep network over time. This feature enables us to rectify false positive and false negative detections over time.

Reporting the 3D universal coordinates of EWC locations using drone configuration and temporal GPS data.

Aluminum Surface Defect Detection

We at Saiwa Inc. are pleased to announce that we have successfully completed an aluminium surface defect detection project in collaboration with AI-innovate Company for CastTechnology in Canada.

In this project, using machine learning techniques and the networks we provide in our Anomaly Detection service, we detect and localize the location of micro and macro defects on a casting line, including: crack, frost, frost patch, longitude frost and mold oscillation. This service is delivered via a simple user interface where users can run the defect detection APIs.

Corrective Exercise mobile application

This is a corrective exercise mobile application which is developed for Android platform. Corrective Exercise is a technique that leverages an understanding of anatomy, kinesiology, and biomechanics to address and fix movement compensations and imbalances to improve the overall quality of movement during workouts and in everyday life. This technique is used to help assess and determine the root cause of imbalances and faulty movement patterns that lead to issues with posture, balance, and total body coordination.

RNA-cleaving Fluorescent DNAzymes (RFDs)

RFDs are DNA sequences that induce a cleavage (cutting) reaction in a substrate strand in response to the presence of a target. In this project, we at saiwa team segmented and measured regions of interest (the dots that constitute the microarray) relative to the background in printed RFD images. Printed microarrays can be used to test for the presence of specific targets (i.e., bacteria). We used around 100 RFD images that were provided by Didar Lab., McMaster uni.

Surface Defect Detection

For a long time, product quality control relies on manual examination in the manufacturing field. In the past several decades, automated surface inspection (ASI) have become more widespread as hardware and software technologies have developed rapidly. To lower labor costs and enhance examination efficiency, more factories start to employ embedded machines for product inspection. ASI platforms use special light sources and industrial cameras to capture the images of the product surface, and machine/computer vision technologies to filter out defective products, which can reduce labor greatly. High-performance cross-product ASI algorithms are urgently needed in manufacturing.

Detection and Surveillance of European Water Chestnut

European water chestnut (Trapa natans) is an invasive floating-leaved aquatic plant that is capable of out-competing native species and altering Ontario’s aquatic ecosystems. In addition to ongoing control of known populations in Ontario, this species is designated as a “Prohibited Species” in Ontario under the Invasive Species Act, 2015 to aid in prevention, detection and control of the species. Ducks Unlimited Canada (DUC) performs surveillance and control of this species in eastern Ontario in attempts to eradicate existing populations and prevent the establishment of new ones.