Paper Surface Defect Detection

Ordered by

AI-innovateChallenge

Maintaining high-quality standards in paper manufacturing is no easy feat—especially when it comes to detecting subtle surface defects. Our client needed a solution that could accurately detect flaws in both white and black paper, two materials with vastly different visual properties.

Maintaining high-quality standards in paper manufacturing is no easy feat—especially when it comes to detecting subtle surface defects. Our client needed a solution that could accurately detect flaws in both white and black paper, two materials with vastly different visual properties.

Our Solution

In collaboration with AI-Innovate, we developed an AI-powered defect detection system as part of our Anomaly Detection service. This cutting-edge solution combines deep learning with smart preprocessing to localize and classify paper surface defects in real-time.

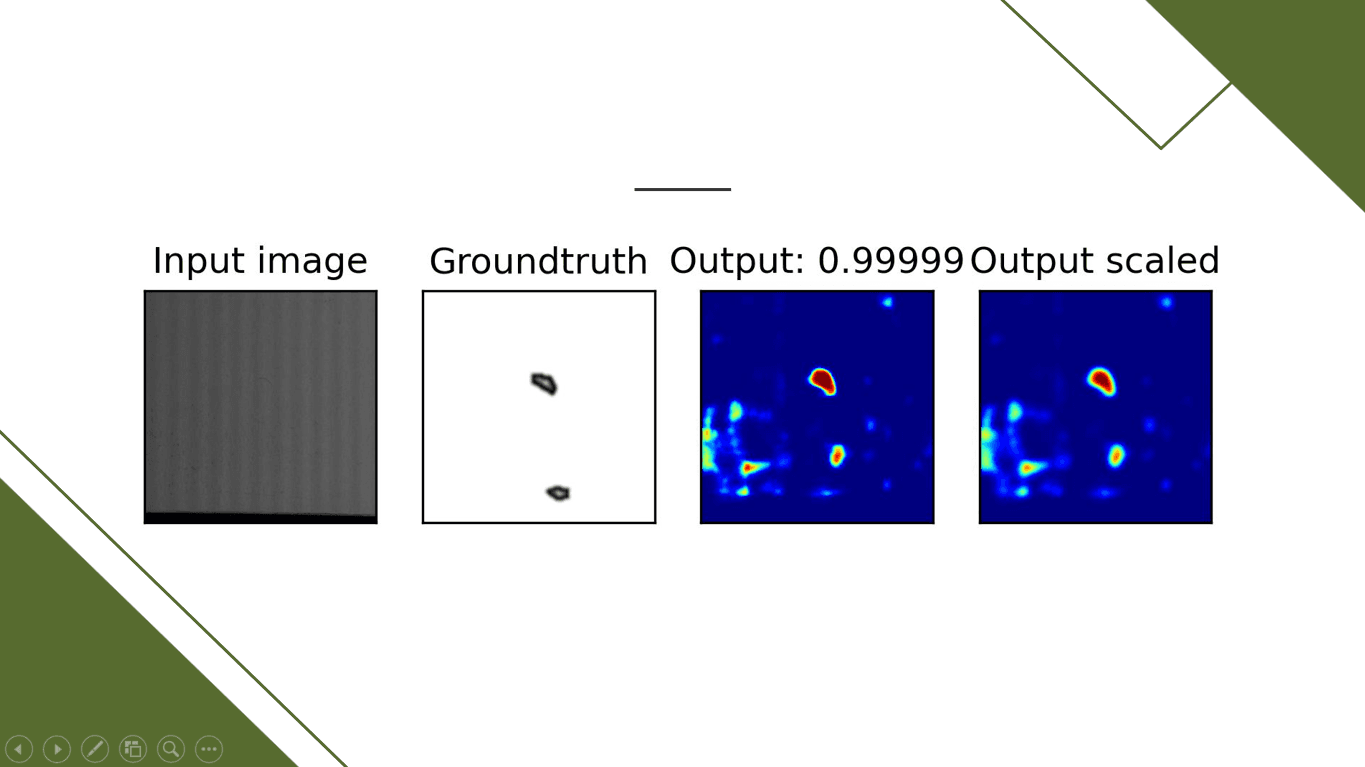

Detection on White Paper

We used advanced machine learning models to detect:

Cracks

Frost marks

Mold oscillations

Longitudinal irregularities

Our custom-built SegDecNet model—a two-stage architecture for segmentation and classification—enabled precise detection.

Detection on Black Paper

Detecting defects on black paper is inherently more difficult due to low contrast. To overcome this, we used our proprietary LLCC contrast enhancement algorithm, significantly improving visibility.

black-paper

Left: Original black paper – Right: Enhanced using LLCC.

Key Technical Highlights

Image Tiling:

Images split into 1024×1024 px tiles for better accuracy and performance

Smart Labeling:

Using Saiwa Annotation Services, we reduced manual labeling while maximizing data quality

Dual-Track Training:

Separate AI models trained for white and black paper to address their unique characteristics

High-Speed Inference:

Models converted to ONNX & TensorRT for GPU-accelerated real-time performance

Results

Automated Quality Assurance:

Significantly reduced manual inspection workload

Real-Time Visualization:

Easy-to-use UI for quick defect review and decision-making

Cost Savings:

Reduced production downtime and material waste

Why Saiwa?

At Saiwa, we specialize in AI solutions for industrial challenges. Our defect detection technologies are:

Fast: Capable of processing high volumes of data with minimal delay

Scalable: Adaptable to various materials—paper, metal, textiles, plastics

Customizable: Integrates seamlessly into your workflow with APIs and intuitive interfaces

Let’s Work Together

If your business depends on speed, accuracy, and consistent quality, Saiwa can help.

Contact us: support@saiwa.ai