Surface Defect Detection

Ordered by

AI InnovateFor a long time, product quality control relies on manual examination in the manufacturing field. In the past several decades, automated surface inspection (ASI) have become more widespread as hardware and software technologies have developed rapidly. To lower labor costs and enhance examination efficiency, more factories start to employ embedded machines for product inspection. ASI platforms use special light sources and industrial cameras to capture the images of the product surface, and machine/computer vision technologies to filter out defective products, which can reduce labor greatly. High-performance cross-product ASI algorithms are urgently needed in manufacturing.

Problem: The manufacturing industry has long relied on manual examination for product quality control. This method is labor-intensive and less efficient. With the advancement of hardware and software technologies, there is a pressing need for Automated Surface Inspection (ASI) systems that can enhance efficiency and reduce labor costs.

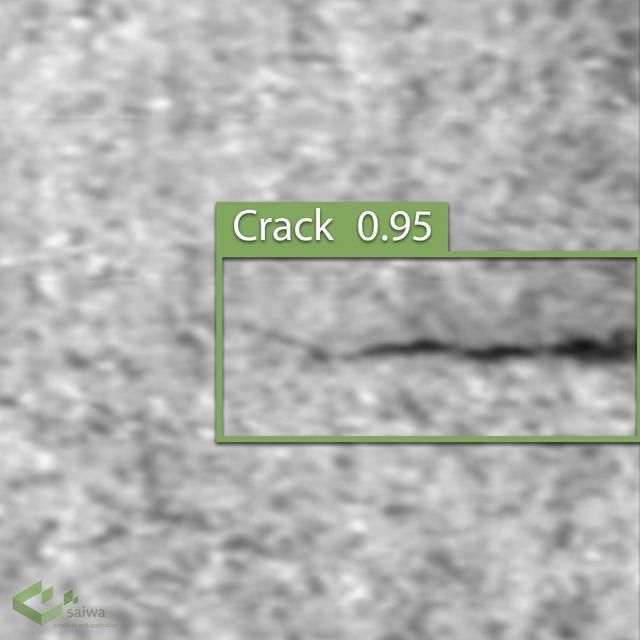

Solution: We have developed an ASI platform employing special light sources and industrial cameras to capture product surface images. We utilized machine/computer vision technologies to identify defects, significantly reducing the need for manual labor. Our team investigated various surface defects across 15 datasets covering metals, steel, polymers, and textures. implemente multiple classification and segmentation deep networks for accurate defect detection. Additionally, a user interface (UI) was provided, allowing customers to test the algorithms and request customization for their specific needs.

Outcome: The project resulted in a substantial increase in the accuracy of defect detection. Automation of the inspection process led to the removal of the human technician role, which in turn reduced manpower requirements and associated costs. This advancement represents a significant step forward in the efficiency and cost-effectiveness of quality control in manufacturing.

Project link: [click here]

Project customer: AI-innovate Company

Read Also: Aluminum Surface Defect Detection