Anomaly Detection Service — Real-Time AI Defect Analysis from Saiwa

Why Choose Saiwa’s Anomaly Detection Service?

When precision defines success, relying on manual inspection is no longer a viable option. This traditional approach is notoriously slow, costly, and unable to detect the microscopic flaws that compromise quality in high-speed production environments.

Saiwa confronts this challenge with an advanced Anomaly Detection Service, engineered to deliver instantaneous and highly accurate defect analysis. To see exactly how our platform delivers these results, we invite you to explore the key technical advantages outlined below and then continue with us to discover the full scope of benefits.

- AI-powered for unsupervised detection of surface defects and outliers: Our system uses sophisticated AI to find imperfections automatically, without human intervention.

- Learns from normal patterns without needing labeled anomalies (unsupervised / semi-supervised): It is trained exclusively on "perfect" samples, enabling it to flag any deviation as a defect. This eliminates the expensive and time-consuming process of data labeling.

- Detects micro and macro defects: capable of detecting a range of defect scales depending on training and resolution,

- High accuracy and speed: Engineered for industrial environments, our platform performs inspections in milliseconds, ensuring that quality checks keep pace with production.

- Customizable to diverse materials and surfaces: The system adapts to various materials, including metal, textiles, plastics, and even organic matter.

Core Capabilities of Saiwa’s Platform

The power of our service is rooted in a set of core technical capabilities designed for seamless integration and robust performance. These features ensure that our platform is not just a tool but a comprehensive solution that embeds intelligence directly into your workflow.

- Unsupervised & Semi-supervised Detection: At its heart, the system excels at learning normalcy to intelligently spot any and all deviations.

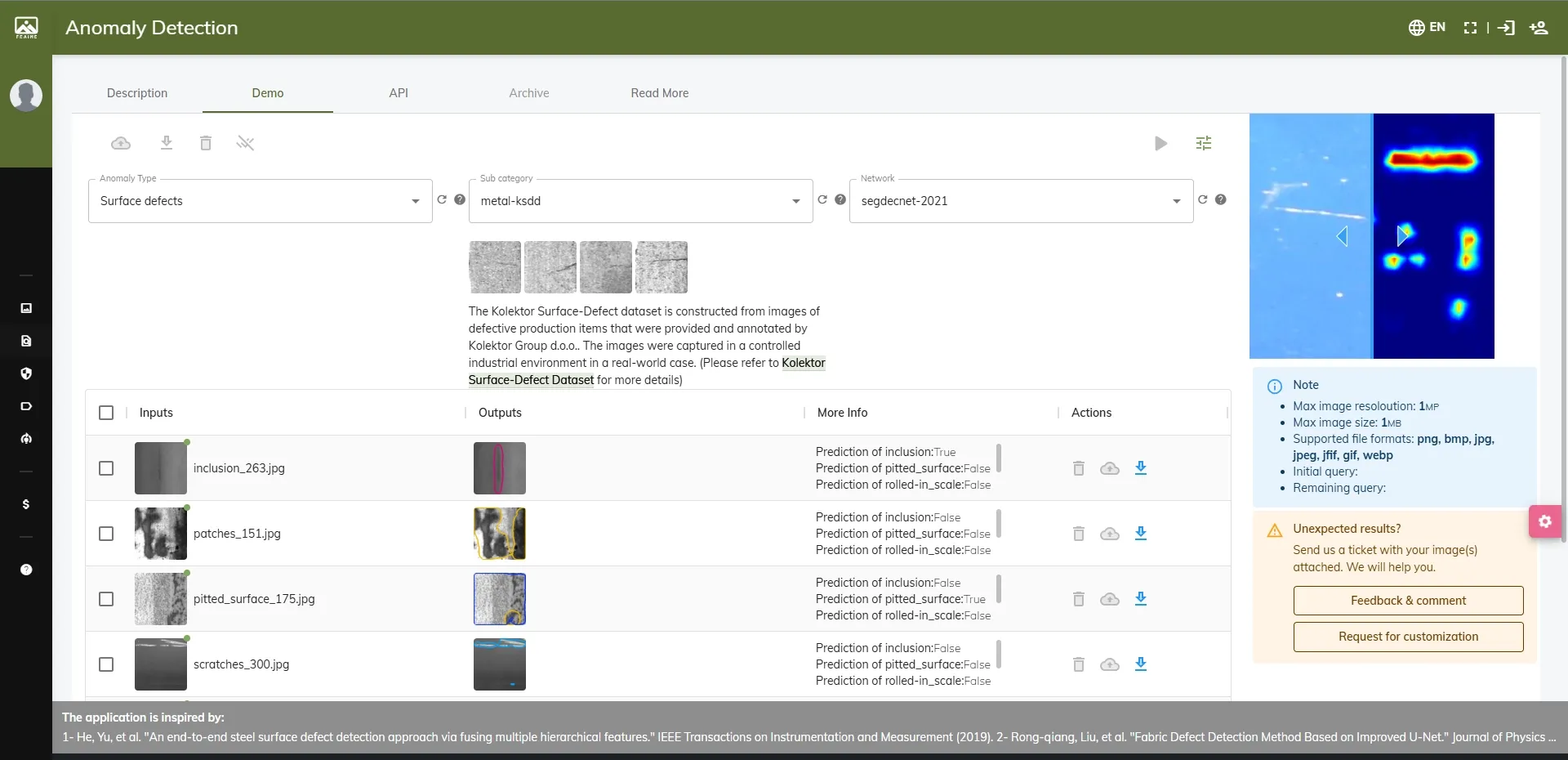

- Spatial Localization of Anomalies: It doesn't just flag a defect; it pinpoints its exact location on a product's surface, often using methods like Bounding box annotation.

- High-Speed Inference: Our optimized models deliver real-time analysis, a critical requirement for integration into fast-moving production lines.

Easy Integration via APIs: The service is delivered via a flexible API, allowing for straightforward integration into existing software and manufacturing execution systems (MES).